Ready for Engineering Filaments

Featuring a 350 °C hotend and a 65 °C actively heated chamber, it supports the entire Bambu filament lineup—from PLA and PETG to PC and PPA.

With closed-loop fan control and precise thermal management, the H2S minimizes warping and deformation while improving layer adhesion.

Build large, high-performance parts that are as functional as they are strong.

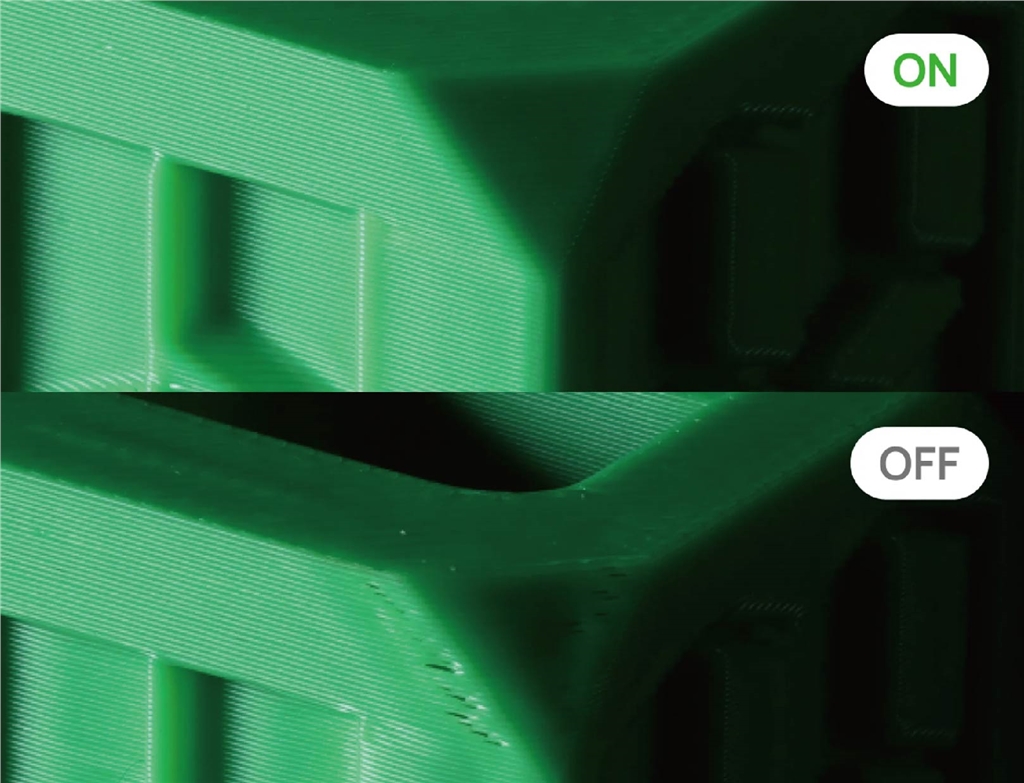

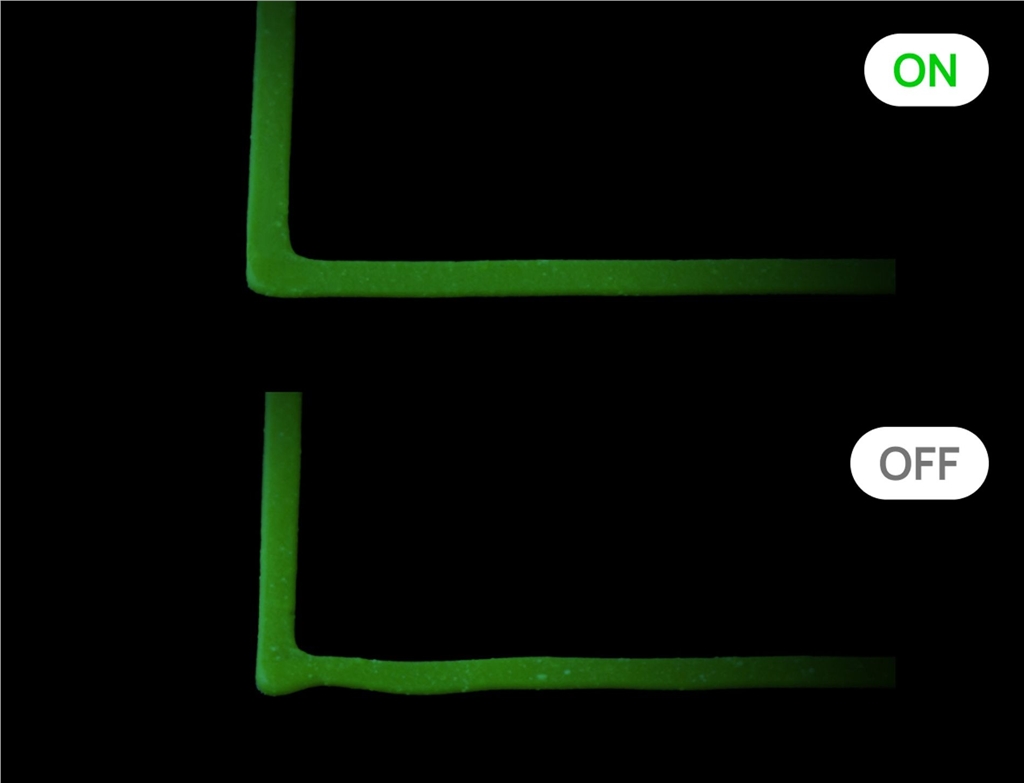

Even Surfaces, Crisp Edges

H2S uses both the sensing capability of its servo motor on the extruder and the high-resolution eddy current sensors on the nozzle to precisely control extrusion by measuring nozzle pressure and calibrating PA parameters for each filament, improving surface smoothness and edge sharpness.

Precision in Motion

Active Vibration Compensation neutralizes micro-vibrations and resonance in real time, enabling premium print quality at higher speeds.

Intelligence That's Got Your Back

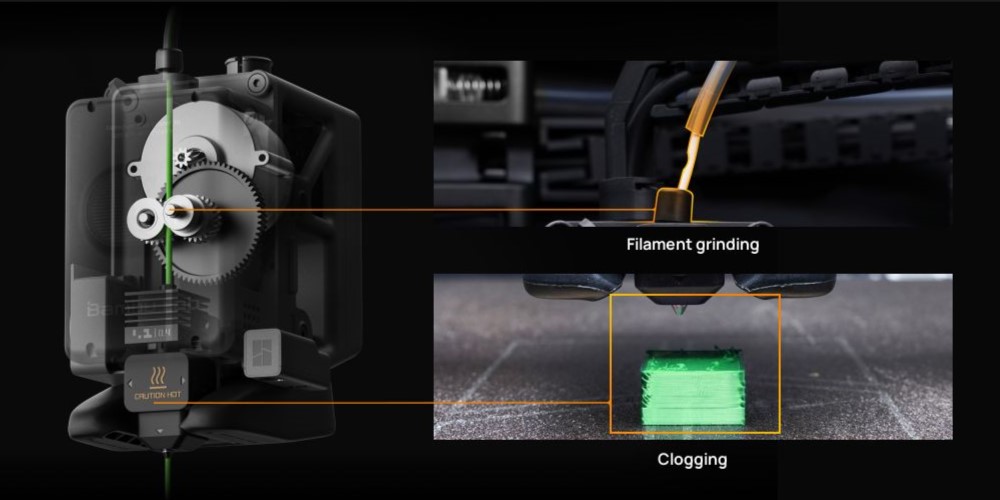

20,000 Checks Per Second,Closed-Loop Feedback, Real-Time Control

Bambu Lab's proprietary PMSM servo system enables 20 kHz resistance and position sampling to dynamically modulate electromagnetic torque vectors. It stabilizes extrusion and actively detects grinding⁽³⁾ or clogs in real time.

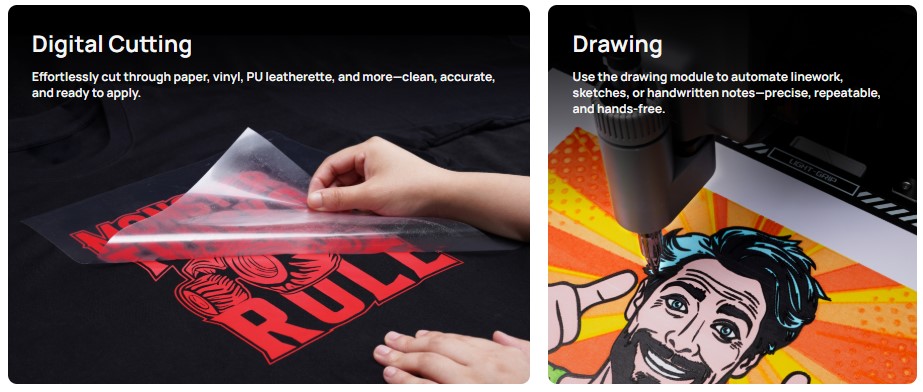

23 Sensors + 3 Cameras

Each Potential Risk Has Its Own Detector

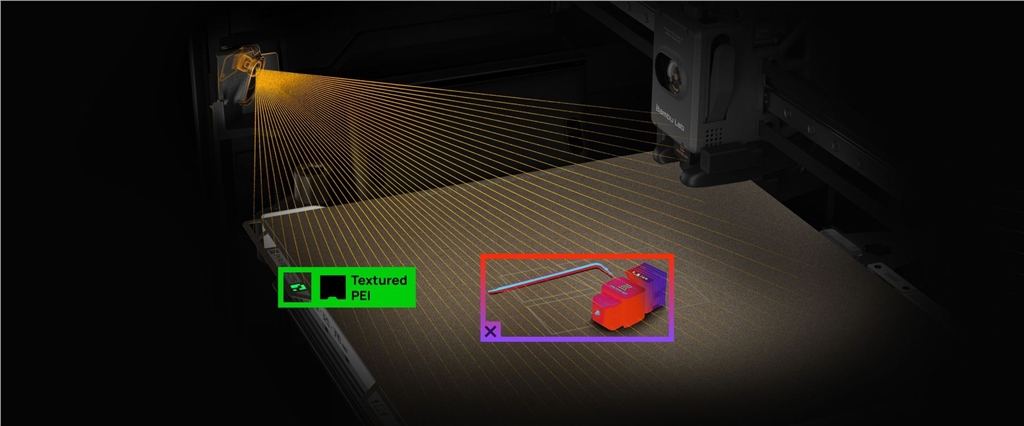

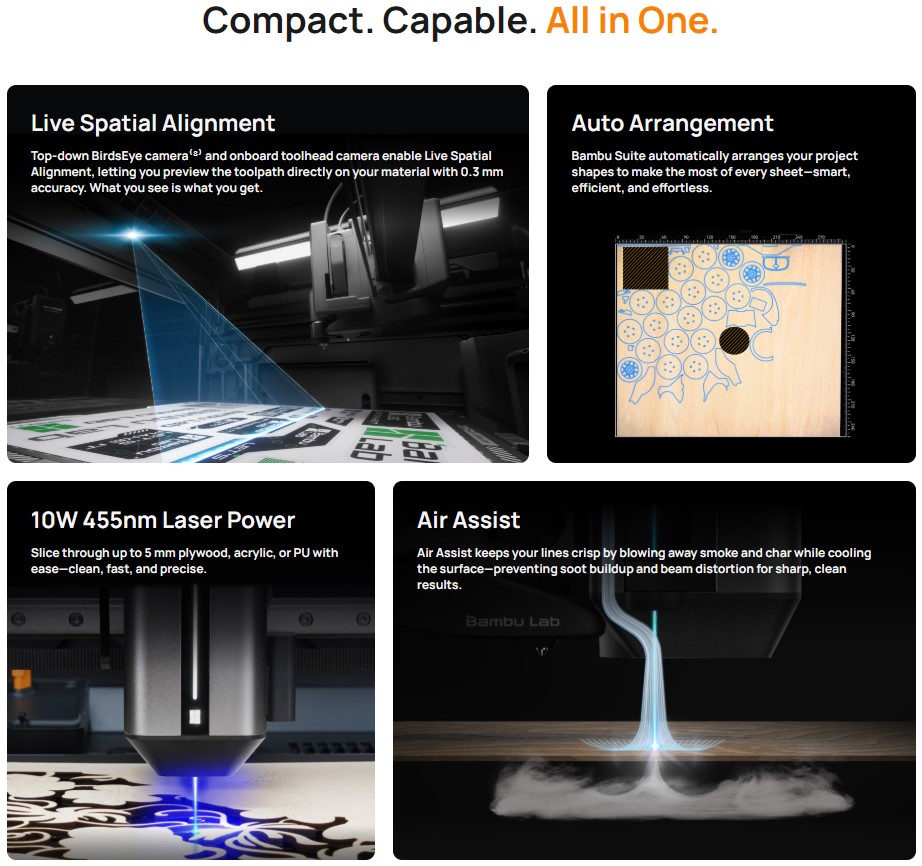

Vision System:

With AI-driven real-time monitoring, the vision system detects clumping, spaghetti and purge chute jamming as they happen, helping prevent failed prints before they start. This same vision system powers advanced features like Live Spatial Alignment, allowing precise laser and cutting calibration, and Vision Encoder technology, which enhances positional accuracy.

Feeding:

With AI-driven real-time monitoring, the vision system detects clumping, spaghetti and purge chute jamming as they happen, helping prevent failed prints before they start. This same vision system powers advanced features like Live Spatial Alignment, allowing precise laser and cutting calibration, and Vision Encoder technology, which enhances positional accuracy.

Filament-path sensors work in unison to monitor feeding speed and position, detect filament tangles and grinding risks, track filament mileage and spool usage, and ensure tool readiness across the AMS, buffer, cutter, and feeding paths, making sure every tool is in place and every move is under control.

Thermal Control:

Five NTC temperature sensors are strategically placed across the nozzle, heatbed, and chamber. Paired with integrated airflow sensors, the system actively monitors and adjusts internal temperatures and circulation, maintaining the ideal print environment through real-time feedback control.

Safety:

The H2S features five flame sensors, front-door and top-cover sensors, and emergency stop button to form a complete safety system. It detects fire risks, monitors enclosure alignment, and allows instant shutdown when needed—protecting your projects and your workspace at all times.

.png)

Pre-Flight Checklist by AI

Prior to each operational cycle, the H2S vision system initiates a comprehensive pre-flight checklist: Chamber Integrity Scan – Detects debris across the entire print surface. Hardware Configuration Audit – Instantly identifies build plate properties.

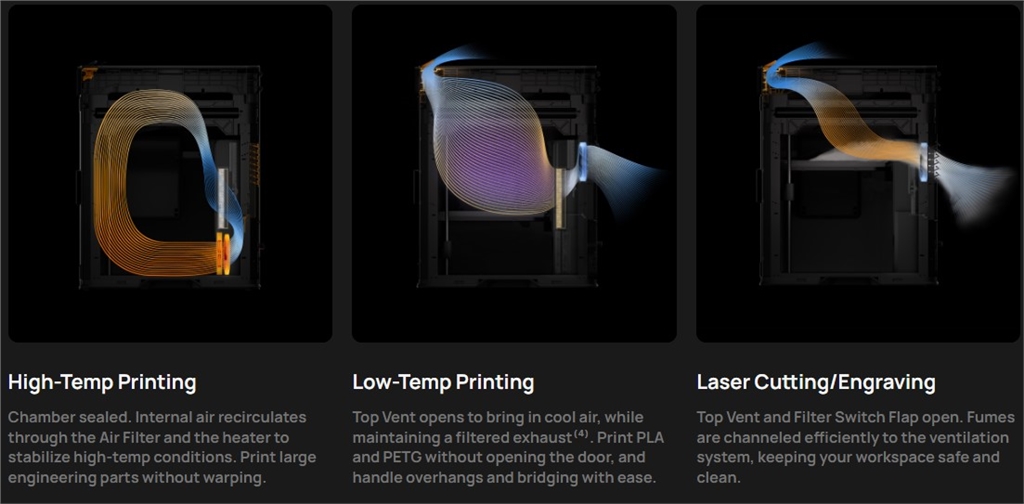

Flap Switch Airflow & Filtration System

3D Printing & Laser Cutting.

3 Modes, All-in-One

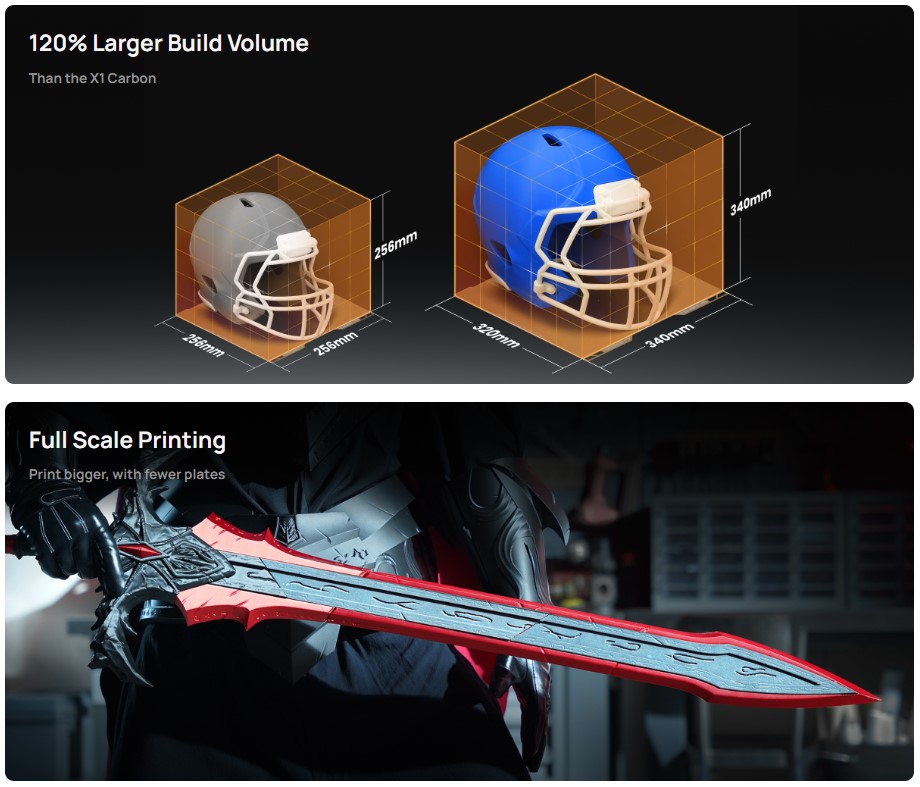

Bigger. Faster. Better.

Maximum Volume. Maximum Productivity.

With a build volume of 340×320×340 mm³, the H2S offers the largest print space among all Bambu Lab printers. Your Vision. Fully Realized in One Print.

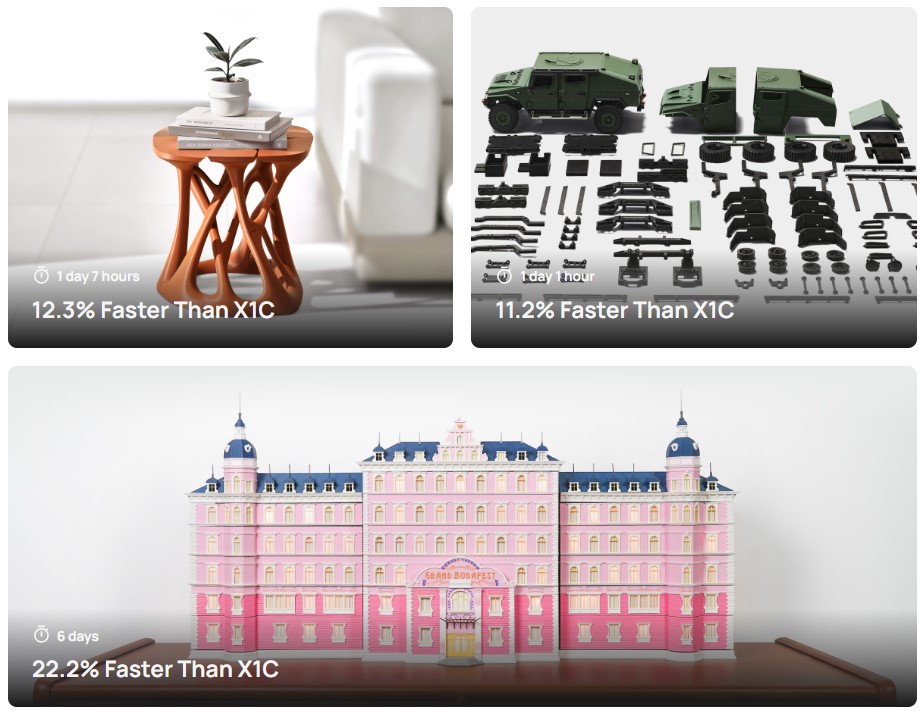

Top Speed. More Reliable Than Ever.

Bambu Lab’s proprietary PMSM⁽⁵⁾ servo extrusion system delivers 67% more extrusion force, providing solid support to high flow⁽⁶⁾ printing. Paired with up to 1000 mm/s toolhead speed and up to 20,000 mm/s² acceleration, your H2S can finally go full throttle—cutting your printing time by up to 30%⁽⁷⁾—while maintaining top-tier quality.

Cut. Engrave. Draw.

Protected Inside and Out

Laser Safety Window: Shields your eyes from the 455 nm laser beam while keeping your workspace clear and visible.

Five Flame Sensors: Advanced sensors continuously monitor for fire risks. If an issue is detected, a loud buzzer and mobile alert⁽⁹⁾ notify you immediately—so you can act fast and stay safe.

Flame-Retardant Chamber: Constructed with fire-resistant materials throughout, the chamber provides passive protection for added safety.

Emergency Stop: Immediately halt operations if something feels off—giving you full control and added peace of mind.

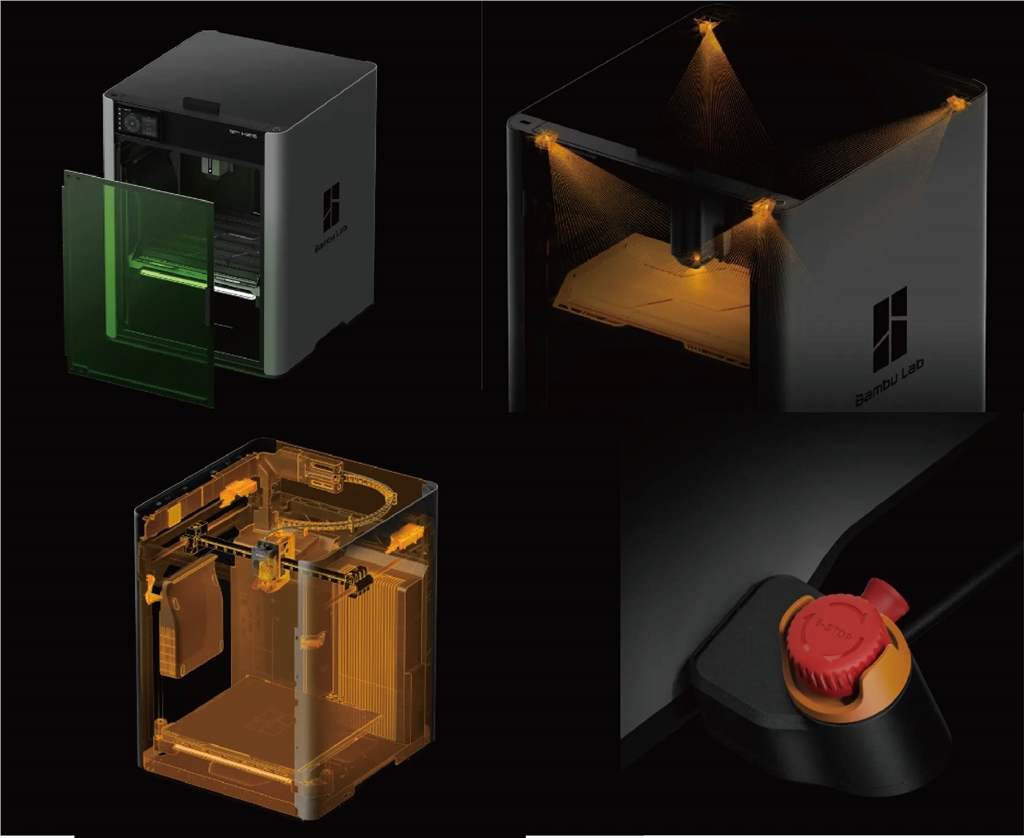

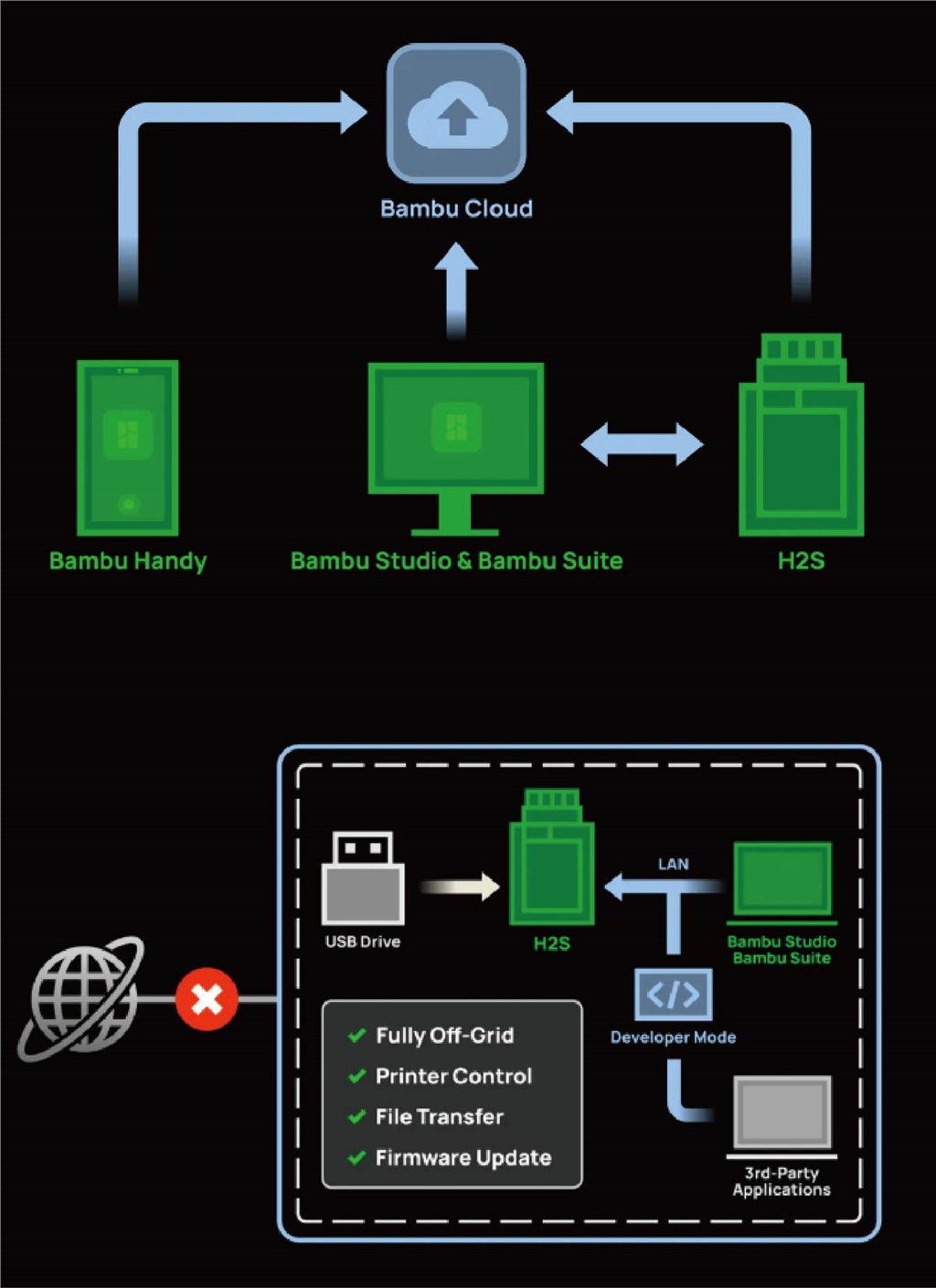

Connectivity, By All Means

Privacy, By Design

The H2S offers seamless cloud connectivity for convenient remote control from any device. For security-sensitive applications, it also delivers complete offline functionality, ensuring physically isolated operation. Users can control the printer, send files, and upgrade firmware—no internet required. Additionally, Developer Mode unlocks MQTT port access, empowering developers and integrators to connect third-party components and custom software with ease.⁽¹⁰⁾

Accessible. Comfortable.

Made to Last.

Quick-Swap Nozzle

Swap nozzles in seconds—no tools, no hassle. Whether you're switching to a high flow hotend or a different nozzle size, the redesigned hotend makes it easy and intuitive, even for first-time users.

Quiet by Design

With Active Motor Noise Canceling and specialized air duct noise-reduction technology, the H2S operates below 50 dB⁽¹¹⁾.

Print overnight or in shared spaces without disrupting your environment.

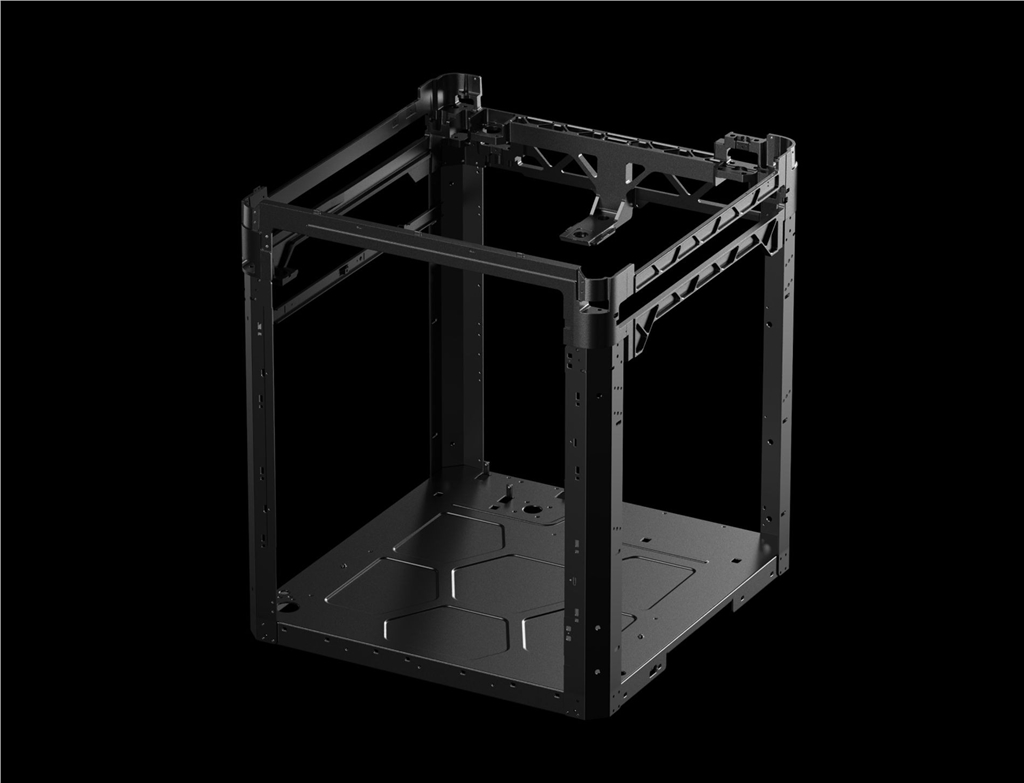

All-Metal, Die-Cast Body

The integrated die-cast aluminum alloy chassis delivers a sturdy, stable structure that provides a rigid foundation for high-speed, large-format printing, while minimizing accuracy loss caused by micro-twisting.

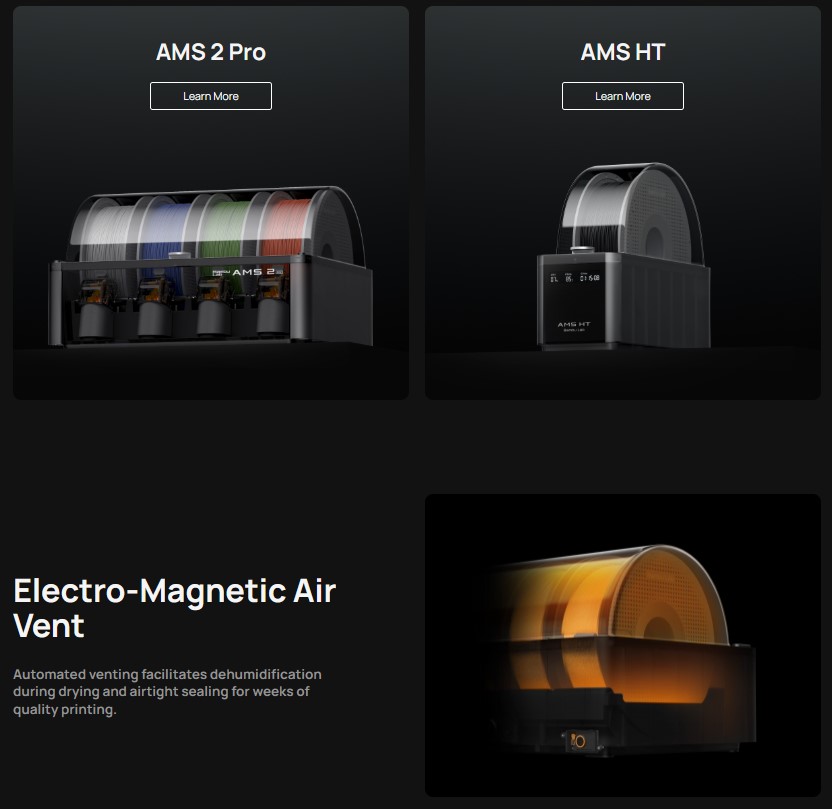

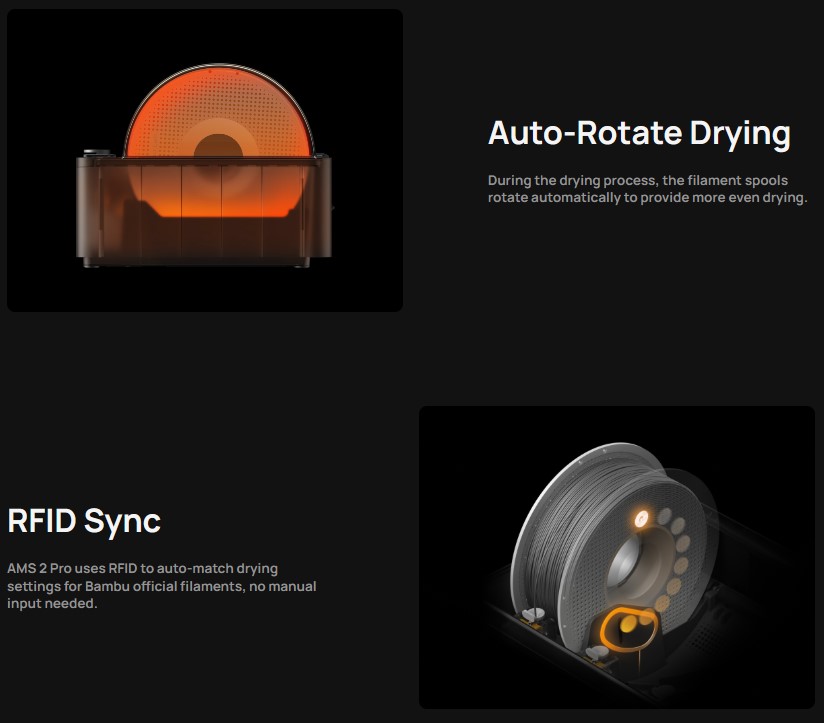

Multi-Color Printing & Drying

All-in-One

Endless Models to Print

Integrated Ecosystem, End-to-End Support

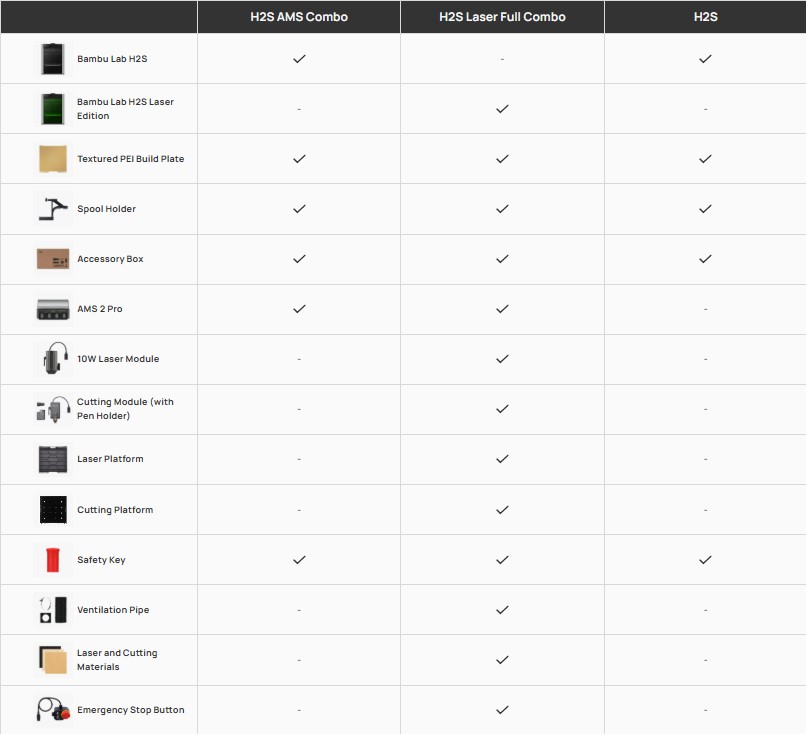

What's in the box

Please note: To ensure the stability of the AMS 2 Pro drying process, use the official Bambu Lab power supply.

Using third-party power supplies may cause product damage. Under the warranty policy, damage to the product itself is not covered.

Contact us to learn more about Bambu Lab 3D Printers!