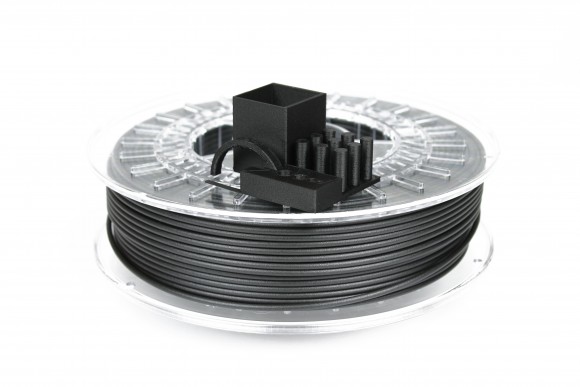

ColorFabb Carbon Fiber XT-CF20

ColorFabb XT CF20 is a copolyester based carbon fibre composite material based on Eastman Chemical's unique Amphora 3D polymer and loaded with no less than 20% specially sourced 3D printable carbon fibres.

The idea of combining carbon fibres in a filament material is not a new one, but ColorFabb has been able to combine a number of desired properties in a single new material:

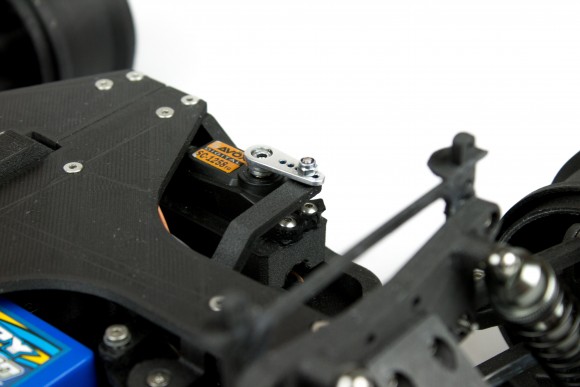

OpenRC used the XT-CF20 for 3D Printing

3D printed rims for OpenRC truggy

Key Features :

• Extreme High Flex Modulus (6.2 GPa) / twice as stiff as PLA

• Moderate strain at break (8-10%), so no extreme brittle filament, but toughness

• High Glass Temp. (Tg = 80C)

• Very high Melt strength

• Very high Melt Viscosity

• Good dimensional accuracy and stability

• Low odor / Styrene Free solution

• Easy processing on many platforms

• Highly attractive matt black surface

Suspension of OpenRC truggy

Servo Link

Carbon Fiber is Abrasive :

Of particular note is the abrasive nature of carbon fibres. In general, these fibres will accelerate nozzle wear on brass nozzles, much faster than unfilled filaments.

ColorFabb recommends the use of stainless steel or hardened copper alloy nozzles.

Torture Test with XT-CF20

Application :

XT-CF20 is a perfect option for applications in all industries.

Functionality, stiffness, dimensional stability, heat resistance, simply impeccable! In the RC industry / drones / aeronautics / automotive / prototype applications, etc. You can use this cable to develop easily.

AMPHORA 3D Polymer

ColorFabb XT-CF20 is made from Eastman Chemical's Amphora 3D Polymer, a copolyester specifically designed for 3D printing.

Its toughness and high melt strength make it ideal for composite fibres, providing the necessary viscosity for 3D printing materials and the production of tough cables and finished products.

-

For the latest version of XT it is recommended to print on a heated plate. The glass plate should be coated with adhesive to ensure the integrity of the first layer.

After printing, the platform should be cooled to approximately 20-30˚C before removing the finished product.

Our experience: Direct drive 3D printers produce slightly finer surfaces, but 3D printers with a Bowden drive, 2.85mm wire and 0.4mm nozzle also produce good results.

Click Here to download the SDS Safety Data Sheet

Click Here to download the TDS Technical Data Sheet

| Nozzle Temperature |

240-260°C |

| Heating Plate Temperature |

60-70°C |

| Printing Speed |

40-70mm/s |

| Net Weight |

0.75KG |

| Material |

XT-Copolyester + |

| Filament Diameter Tolerance |

±0.1mm |

| Glass Transformation Temperature |

75°C |

| Applicable Minimum Nozzle |

0.4 mm |